Helping a Greek Laundry Serve Tourists, One Towel at a Time

The Situation

Astor S.A. is a commercial laundry that for the past 10 years has provided high quality linen service to the food service segment on the island of Crete in Greece. The laundry serves approximately 200 hotels and tourist accommodation entities, delivering fresh, clean linen within 24 hours to any location in Crete. Due to the seasonal nature of the business, the laundry operates only during the summer months of the year, making productivity and resource optimization even more essential.

Over the last two years, Astor and Ecolab have implemented several laundry optimization solutions to ensure sustainable business growth for Astor, while helping to preserve the natural beauty of the surrounding environment.

The Solution

Wastewater limits on the island are very strict. Astor and Ecolab agreed to work together to reuse as much water in the washing process as possible to reduce the laundry’s freshwater consumption. These efforts also serve to reduce the amount of wastewater that goes into the sewer, minimizing the risk of penalties and helping the business grow responsibly.

The team decided to focus on reducing the press water volume. Press water is the water that is pressed out from clean textiles at the end of the washing process with a continuous batch washer. This water is clean and can be reused in the different phases of the washing process. By sending the water back into the process, we can reduce the amount of water that gets drained into the sewer and it also means we use less fresh water in the process.

Ecolab’s AquaCatch, a press water recycling unit, has been connected to both continuous batch washers at the laundry. This unit measures press water with its inductive flow meter and ensures highly efficient rinsing with the programmed rinse water volume.With the help of this technology, the consumption of the fresh water has been reduced by 1.5 liters per kilogram, saving almost 9,000 cubic meters per year which is helping the business to thrive.

Reusing as much water in the washing process as possible helps the laundry grow responsibly.

The next Step

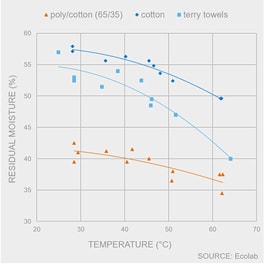

Hot rinsing shortens drying times and therefore increases the drying capacity as well as the volume of textiles washed per hour.

The Results

By implementing several water and energy solutions, the following goals have been achieved:

- Water savings of more than 9,000 cubic meters per year. This is equivalent to the annual drinking water needs of 8,200 people.

- 15 percent higher capacity of textiles being processed

Following the success of these projects, we’ve also introduced EU Ecolabel-certified washing program OxyGuard40. The Ecolabel certificate and future projects to optimize laundry operations will not only help Astor expand its business, but will also allow the island of Crete to preserve its environment and remain a top location for tourism in Europe.

Related Stories

Visitors who viewed this story also viewed